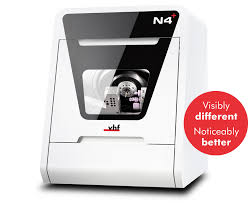

N4+

Brand: VHF

VHF N4+ Dental Milling Machine – Accuracy and Performance in Wet Milling

The VHF N4+ is a 4-axis dental milling machine designed exclusively for high-precision wet milling. Ideal for labs and clinics that need a reliable solution for materials such as glass-ceramics, composites, titanium and zirconia, the N4+ combines speed, power and a compact design. With a spindle that reaches 80,000 RPM and an optimized cooling system, the N4+ is the ideal choice for those looking for continuous performance with high quality.